Hydraulichord

In the Autumn of 2004, I have developed - as a continuation of the UltraTonal Piano Project - a “Hydraulic Tuning Pin” design, otherwise dubbed the “Hydraulichord”, that can tune piano strings with high precision.

My senior colleague, Textile M. Sc. Uğur Keçecioğlu has created an executable program in order to portray how the Hydraulichord works. Below, you can watch a video I acquired from said program which shows the operation of the Hydraulichord.

Hydraulichord works in the following manner:

-

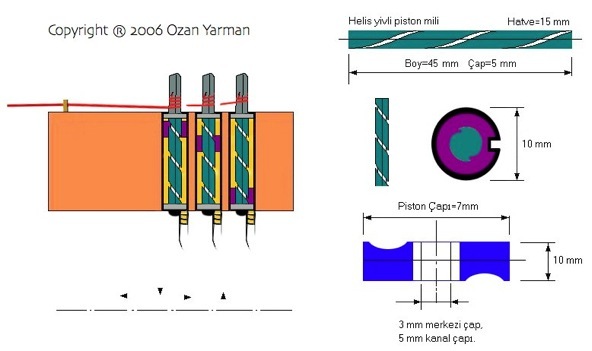

1.The piano string is tied to a pin with a helical mortice. The pin, clenched from the top and bottom, rotates inside a hydraulic cylinder.

-

2.The cylinder is divided into two seperate isolated chambers by a stopple which moves up or down abreast the pin’s mortice.

-

3.When fluid pressure is applied from the distal end of the cylinder to a chamber, the stopple, following the helical mortice of the pin, moves in the direction of the rotational axis of the pin. A steel ball is utilized to provide contact and friction between the stopple and the pin’s mortice.

-

4.The up-down motion of the stopple results winding or unwinding of the string by the pin.

Due to the fact that it will not be possible to insert a Hydraulichord into the tuning pin hole of an ordinary piano, it is necessary to dismantle the laminate wood blocks and to mount in their place built-of-one-piece hydraulic units that incorporate one Hydraulichord per string.

A schema displaying the technical particulars of the Hydraulichord is presented below:

In any case, for adjusting +200 Hydraulichords one by one, it will be required to design a control system and an ancillary electro-mechanical main console.